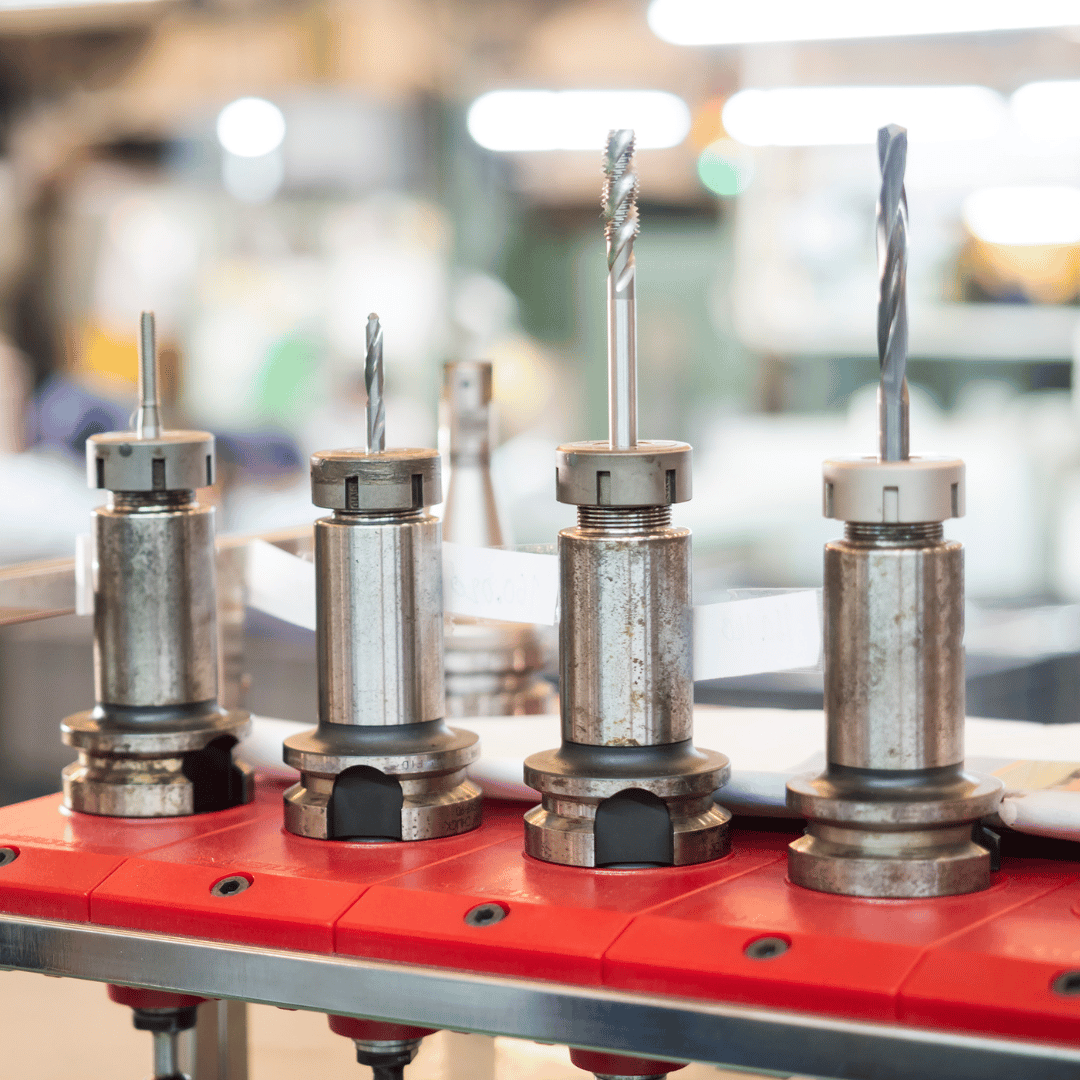

Carbide Tools

Carbide Tools and Inserts are the most widely used tools in the Machining Industry for the last few decades. Carbide is a Chemical Compound composed of Carbon along with a less electronegative element than Carbon itself.

Step Drills: 2 Step, 3 Step, 4 Step

Non Standard Drills any size (3-28 MM)

Flat Bottom Drills

3 Flute Drills High Feed

Thru-Coolant Drills: 2 Hole & 3 Hole

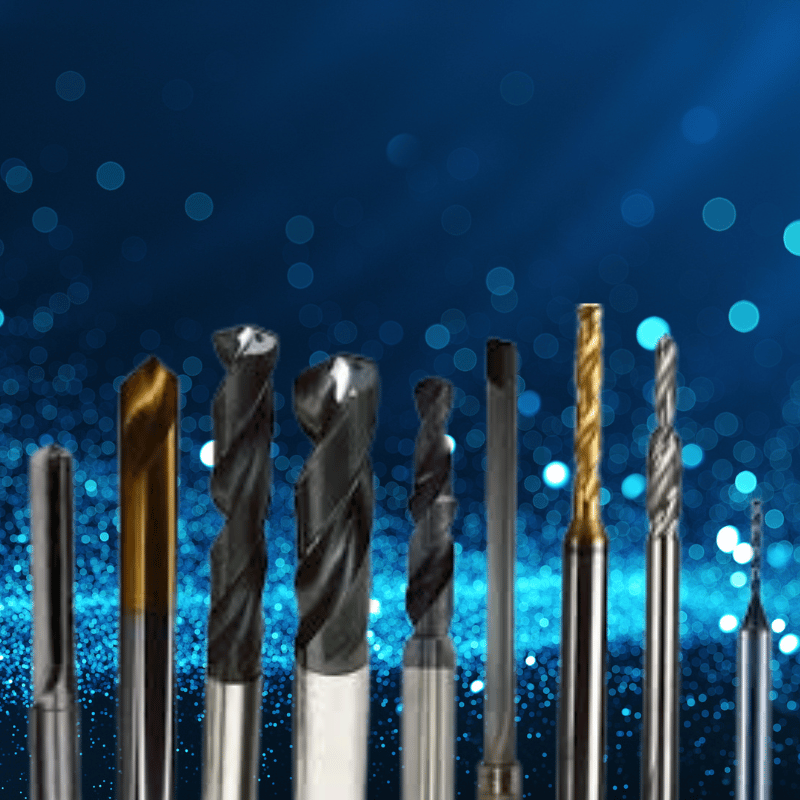

Carbide Drills

- Step Driils: 2 Step, 3 Step, 4 Step

- Non Standard Drills any size (3-28 mm)

- Flat Bottom Drills

- 3 Flute Drills High Feed

- Thru-Coolant Driils: 2 Hole & 3 Hole

1. Step Drills: 2 Step, 3 Step, 4 Step

Step drills, also known as unibits or step bits, are specialized drill bits that are used to create holes in thin materials. They have a conical shape with multiple stepped sizes, allowing them to create holes of various diameters in a single pass. Step drills are commonly used to create holes in sheet metal, plastic, and other thin materials.

Advantages of Step Drill: 2 Step, 3 Step, 4 Step

- Can create multiple hole sizes

- Versatility

- Time-saving

- Durability

- Convenience

- Accuracy

- Ease of use

- Cost-effective

- Compact size

- Safe

2. Non Standard Drills any size (3-28mm)

Non-standard drills refer to drill bits that are not typically used for standard drilling applications. These can include specialized drill bits that are designed for specific materials or applications, or drill bits that have non-standard shapes or sizes.

Benefits of Non Standard Drill any size (3-28 mm)

- Improved Accuracy

- Enhanced Durability

- Increased Versatility

- Improved Efficiency

- Enhanced Safety

- Reduced Wear

- Increased Precision

- Improved Quality

- Enhanced Performance

- Cost-Effectiveness

3. Flat Bottom Drills

Flat bottom drills, also known as spot facing drills, are specialized drill bits that are used to create flat, precise holes in a variety of materials. They are typically used when a flat bottom is desired in the drilled hole, such as when creating a countersink or when installing a screw or bolt in a flat surface.

Applications of Flat Bottom Drills

- Creating Countersinks

- Installing screws or bolts

- Machining

- Metalworking

- Woodworking

- HVAC

- Electrical

- Plumbing

- Automotive

- Aviation

4. 3 Flute Drills High Feed

3-flute drills with high feed rates are specialized drill bits that are designed for efficient and precise drilling in a variety of materials. They are characterized by having three flutes, or spiral grooves, on the cutting edge of the drill, which help to remove material as the drill cuts through the material.

Applications of 3 Flute Drills High Feed

- Machining

- Metalworking

- Woodworking

- HVAC

- Electrical

- Plumbing

- Automotive

- Aviation

- Aerospace

- Construction

5. Thru-Coolant Drills: 2 Hole & 3 Hole

Thru-coolant drills, also known as through-coolant drills, are specialized drill bits that are designed to allow coolant to pass through the center of the drill while it is in use. Thru-coolant drills are available in two-hole and three-hole designs, which refer to the number of channels in the drill that allow the coolant to pass through.

Applications of Thru-Coolant Drills: 2 Hole & 3 Hole

- Machining

- Metalworking

- Woodworking

- HVAC

- Electrical

- Plumbing

- Automotive

- Aviation

- Aerospace

- Construction

Message Us

Get In touch below. For Heavy Industry Solutions

Call Us

(+91) 9811201119

Office Location

Plot No. 49-B, Bhakari-Pali Road, Pali Industrial Area, Faridabad-121001, Haryana

Open Hours

24*7 Days Working

sales@raxsonstool.com