Custom Tools

This type of tool is often used in manufacturing and quality control settings, where precise measurements are important. The custom tool will depend on the type of measurement being taken and the characteristics of the object or surface being measured.

Outer Radius Tool

Back Chamfer Tool

Step Profile Drills

T Slot Cutter Tool

Custom Tools

- Outer Radius Tools

- Back Chamfer Tools

- Step Profile Drills

- T Slot Cutter

1. Outer Radius Tool

Outer Radius Tools are tools that are designed for use in machining operations where the outer radius of a workpiece needs to be machined or shaped. Outer Radius Tools are typically used to create precise and consistent outer radii on workpieces, and they are often made from high-quality materials such as carbide or high-speed steel to ensure durability and accuracy. There are a wide variety of Outer Radius Tools available, including end mills, turning tools, and grinding wheels, each of which is designed for specific machining applications.

Applications of Outer Radius Tool

- Creating rounded edges on parts such as gears, bearings, and other mechanical components.

- Machining the outer radius of a workpiece in a turning operation, such as on a lathe.

- Finishing the outer surface of a workpiece by using a grinding wheel with an outer radius.

- Milling the outer radius of a workpiece using an end mill with an outer radius.

- Shaping the outer radius of a workpiece in a forging or casting operation.

2. Back Chamfer Tool

A back chamfer tool is a cutting tool that is used to create a chamfer or bevel on the backside of a workpiece. A chamfer is an angled surface that is typically created at the edge of a workpiece to remove sharp corners or edges and to improve the appearance of the finished part. A back chamfer is created on the backside of a workpiece, as opposed to the front or top side.

Applications of Back Chamfer Tool

- Creating a chamfer on the backside of a workpiece to remove sharp corners or edges.

- Improving the appearance of the finished part by creating a bevel on the backside of a workpiece.

- Removing the excess material from the backside of a workpiece in a machining operation.

- Creating a chamfer on the backside of a workpiece to improve the fit and function of the part.

- Chamfering the backside of a workpiece to prepare it for further machining or finishing operations.

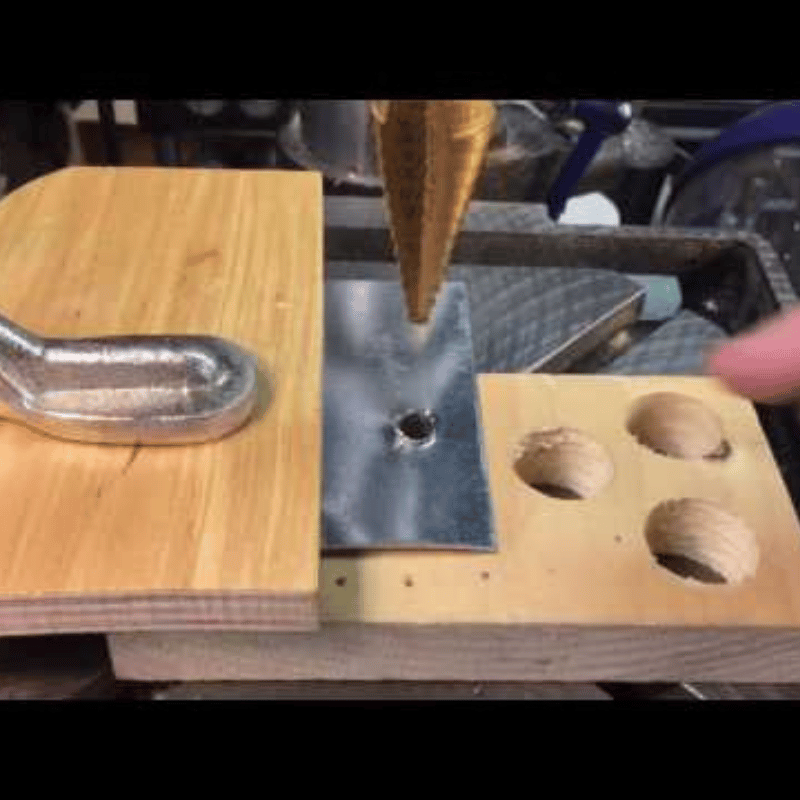

3. Step Profile Drill

A step profile drill is a type of cutting tool that is used to create precise and consistent holes with stepped or tapered profiles. These drills are typically used in drilling operations, and they can be used on a variety of materials including metal, plastic, and wood. Step profile drills are commonly used in the manufacturing of mechanical components, automotive parts, and other precision parts where the hole profile is important for the function or performance of the finished part.

Applications of Step Profile Drill

- Creating precise and consistent holes with stepped or tapered profiles in a drilling operation.

- Drilling holes with specific tolerances or profiles that are required for certain applications.

- Drilling holes in mechanical components and automotive parts that require precise hole profiles.

- Creating holes with stepped or tapered profiles in plastic, metal, or wood.

- Drilling holes in materials with hard or abrasive surfaces, such as stainless steel or cast iron.

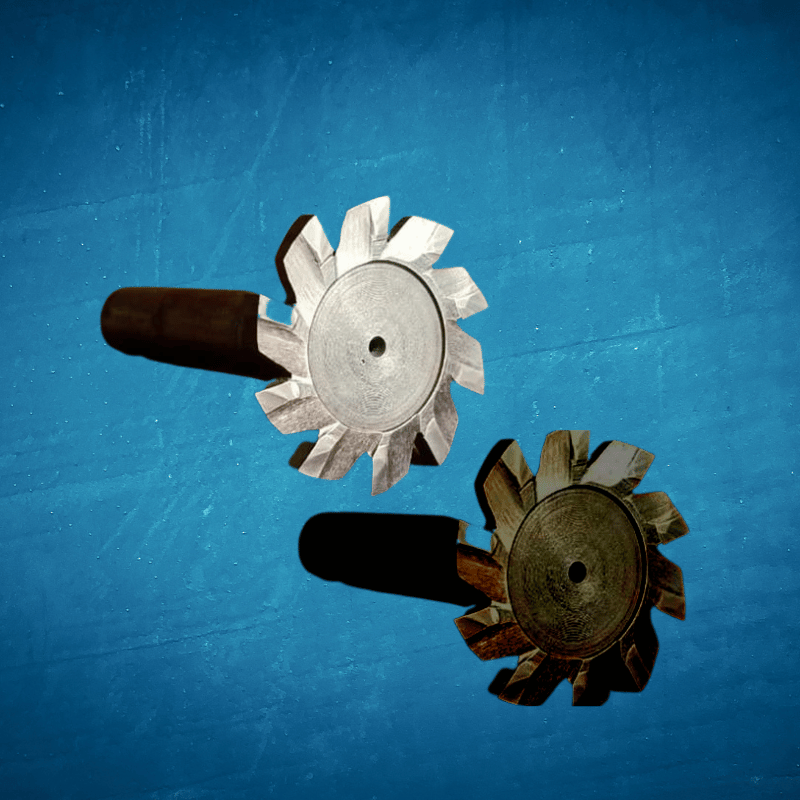

4. T-Slot Cutter

A T-slot cutter is a type of cutting tool that is used to create T-shaped slots or channels in a workpiece. T-slots are commonly used in the manufacturing of machine components and other parts where the T-slot is used to hold or secure the part in place. T-slot cutters are typically used in milling operations, and they can be used on a variety of materials including metal, plastic, and wood.

Applications of T-Slot Cutter

- Creating T-shaped slots or channels in a workpiece for holding or securing purposes.

- Machining T-slots in machine components and other parts require precise T-slots for proper functioning.

- Creating T-slots in jigs, fixtures, and other tooling components for clamping or positioning purposes.

- Machining T-slots in workpieces are made from a variety of materials, including metal, plastic, and wood.

- Creating T-slots in workpieces with complex or unusual geometry, such as curved or angled surfaces.

Message Us

Get In touch below. For Heavy Industry Solutions

Call Us

(+91) 9811201119

Office Location

Plot No. 49-B, Bhakari-Pali Road, Pali Industrial Area, Faridabad-121001, Haryana

Open Hours

24*7 Days Working

sales@raxsonstool.com