Our Machinery

Machinery refers to a group of machines or devices that are used to perform a specific task. This can include simple machines like levers and pulleys, as well as more complex machines like automobiles and industrial robots.

Cylindrical Grinding

Surface Grinding

Conventional T&C

Lathe Machine

WIDMA RX5

WIDMA EZEEGRIND

WALTER

TGT

Measurement Machine

Our Machinery

- Cylindrical Grinding

- Surface Grinding

- Conventional T&C

- Lathe

- Widma RX5

- Widma Ezeegrind

- Walter

- TGT

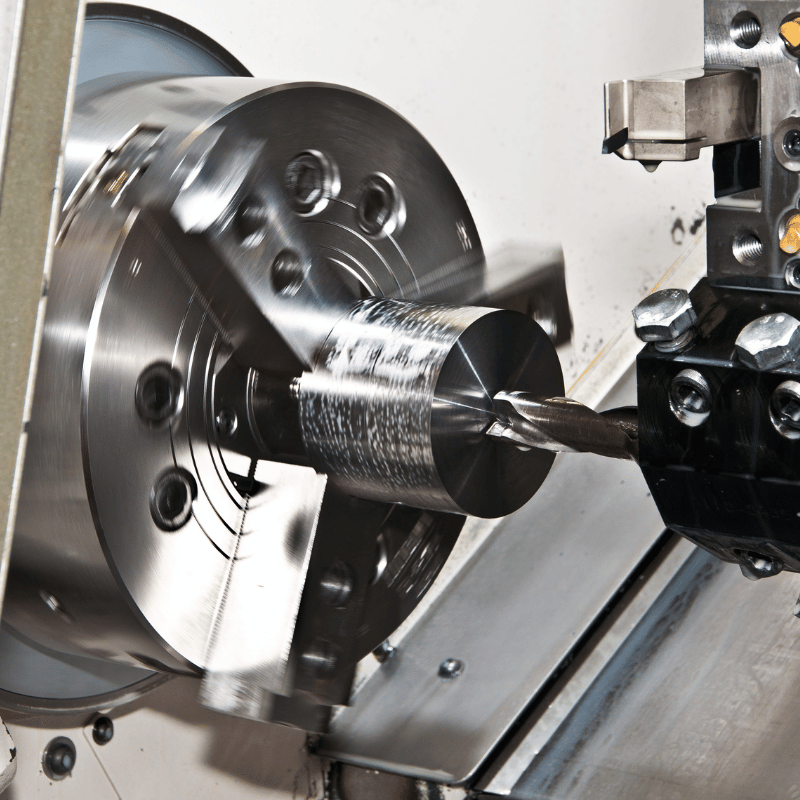

1. Cylindrical Grinding

Cylindrical grinding is a type of grinding that is used to shape the outside of an object. The grinding is done with a cylindrical grinding machine, which rotates the object while a grinding wheel is pressed against it to grind the object down to the desired shape. Cylindrical grinding is often used to make precision parts, such as those found in the automotive and aerospace industries. It is a highly accurate method of grinding that can produce parts with tight tolerances and a smooth finish.

Applications of Cylindrical Grinding

-

Grinding the outside of objects to create a precise shape and smooth surface finish.

-

Grinding the ends of cylindrical objects to create a precise length and straightness.

-

Grinding the surfaces of gears to create precise tooth shapes and profiles.

-

Grinding the bores of bearings and other cylindrical components to create precise inner diameters.

-

Grinding the outer diameters of pipes and tubes to create precise diameters and straightness.

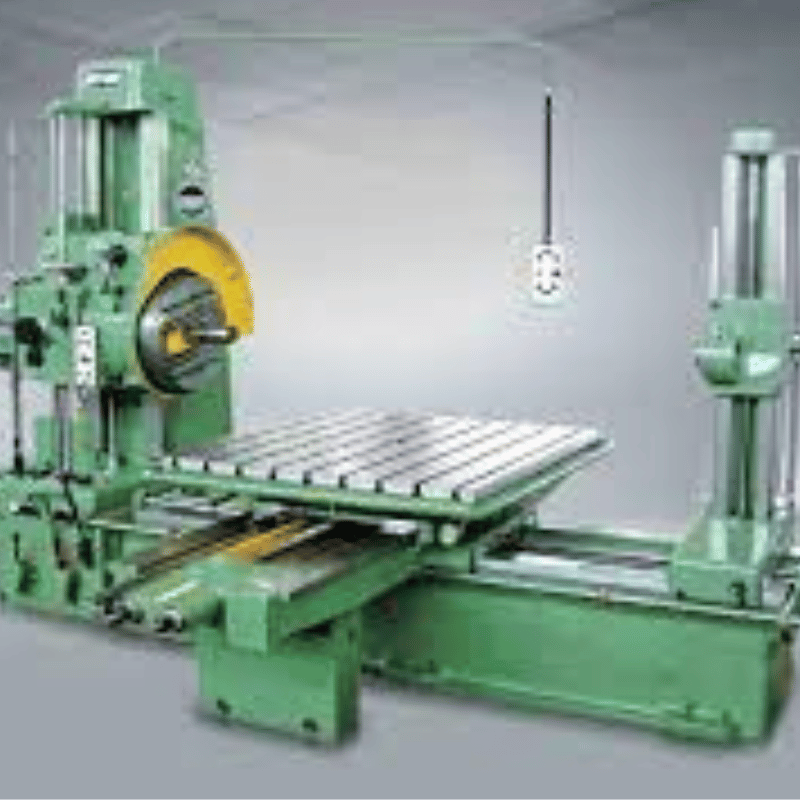

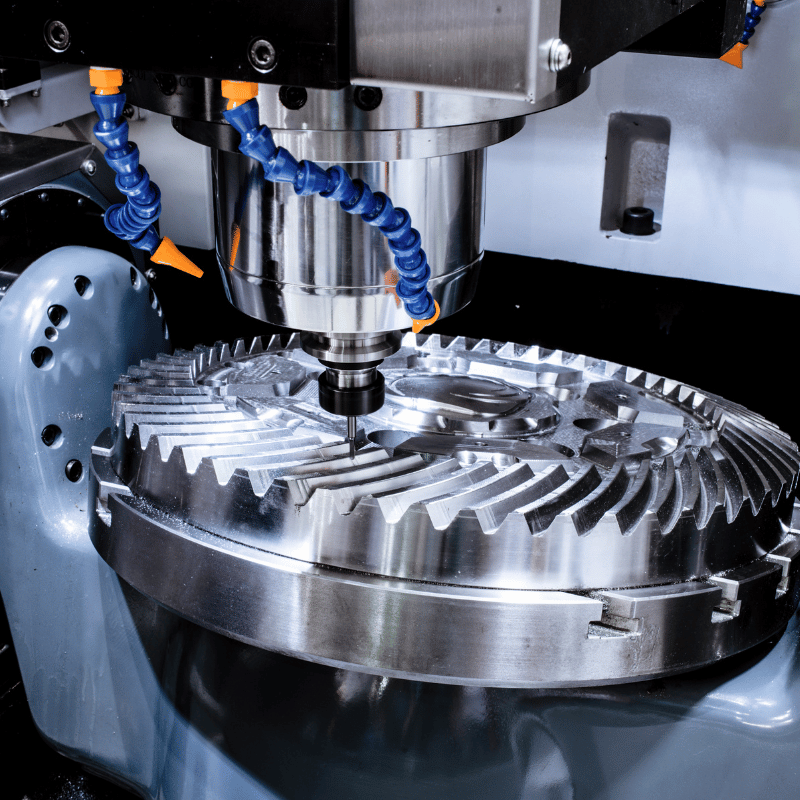

2. Surface Grinding

Surface grinding is a process that is used to smooth the surface of a workpiece by removing material from the top layer. It is typically done using a grinding machine, which is a machine tool that uses an abrasive wheel to grind the workpiece down to the desired shape and finish. Surface grinding is often used to create a precise, flat surface on a workpiece, or to achieve a smooth finish on a rough, irregular surface. It is also used to create a specific pattern or texture on the surface of a workpiece.

Applications of Surface Grinding

- Grinding the flat surfaces of machine parts to create precise shapes and dimensions.

-

Grinding the surfaces of automotive and aerospace parts to create precise shapes and finish.

- Grinding the surfaces of bearings and other machine parts to create a smooth finish.

- Grinding the surfaces of molds and dies to create precise shapes and finishes.

- Grinding the surfaces of tools and cutters to create precise shapes and sharp edges.

3. Conventional T&C

Conventional tool and cutter grinding refers to the manual grinding of tools and cutters using a grinding machine. In this process, the workpiece is held in a vise or fixture and the grinding wheel is manually moved over the surface of the workpiece to grind it down to the desired shape and finish. This method of grinding is often used to produce simple, standard shapes and sizes of tools and cutters, such as those used in the metalworking and woodworking industries.

Applications of Conventional Tools & Cutter

-

Grinding the cutting edges of lathe tools and milling cutters to create precise shapes and sharpness.

-

Grinding the shapes of drill bits to create precise drilling profiles.

-

Grinding the shapes of reamers to create precise hole sizes and finish.

-

Grinding the shapes of taps to create precise thread profiles.

-

Grinding the shapes of saw blades to create precise cutting edges.

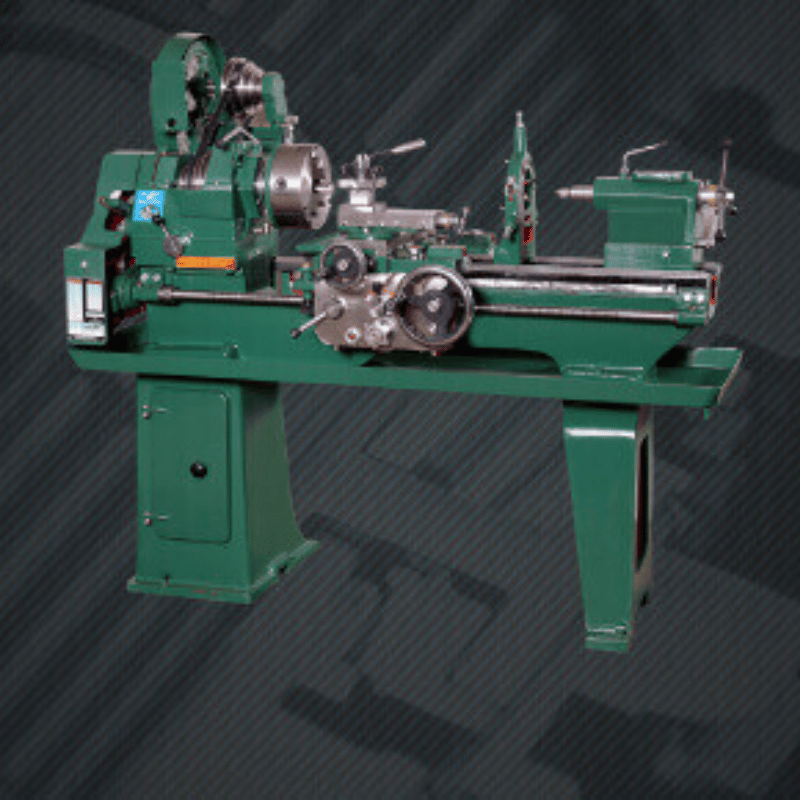

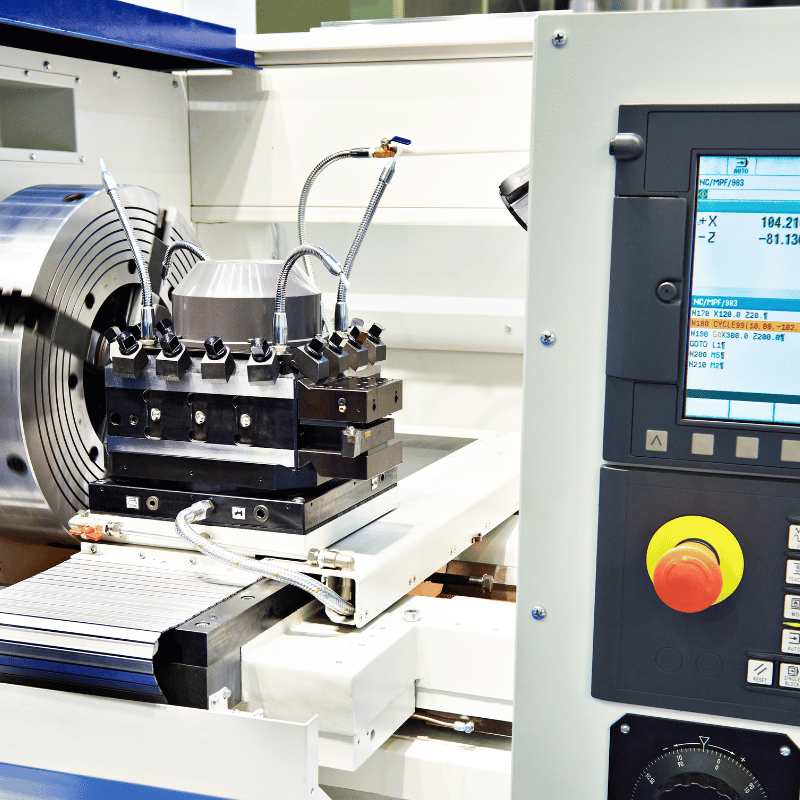

4. Lathe

A lathe is a machine tool that rotates a workpiece on its axis to perform various operations such as cutting, sanding, and drilling. Lathes are used to shape a variety of materials, including wood, metal, and plastic. The workpiece is typically held in place by a chuck, which is a clamp that holds the workpiece firmly in place while it is being machined.

The lathe also has a cutting tool, which is mounted on a carriage and fed into the workpiece to remove material and create the desired shape. Lathes are used in a wide range of industries, including the automotive, aerospace, and construction industries.

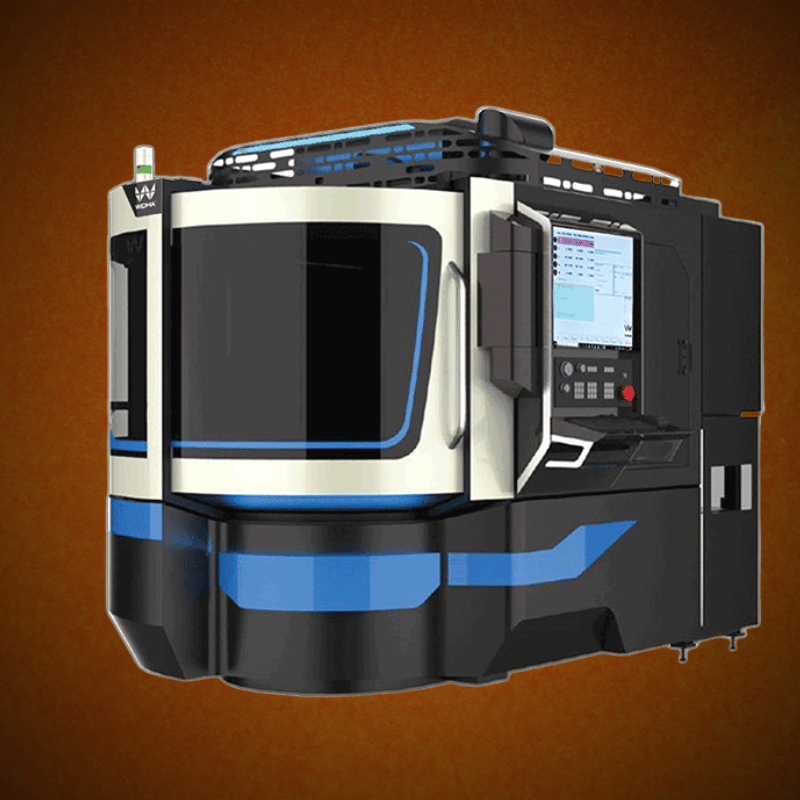

5. WIDMA RX5

WIDMA RX5 is a type of CNC (Computer Numerical Control) machine tool manufactured by WIDMA (Windsor Machines Limited). WIDMA is an Indian company that specializes in the design and manufacture of CNC machine tools and other manufacturing equipment. The WIDMA RX5 is a multi-axis CNC machining center that is designed for high-precision machining operations

Key Features od WIDMA RX5

- High-Performance Spindle

- An advanced control system

- Wide range of tool holders and work-holding devices

- Designed for easy setup and operation

- Well-suited for use in a variety of manufacturing environments

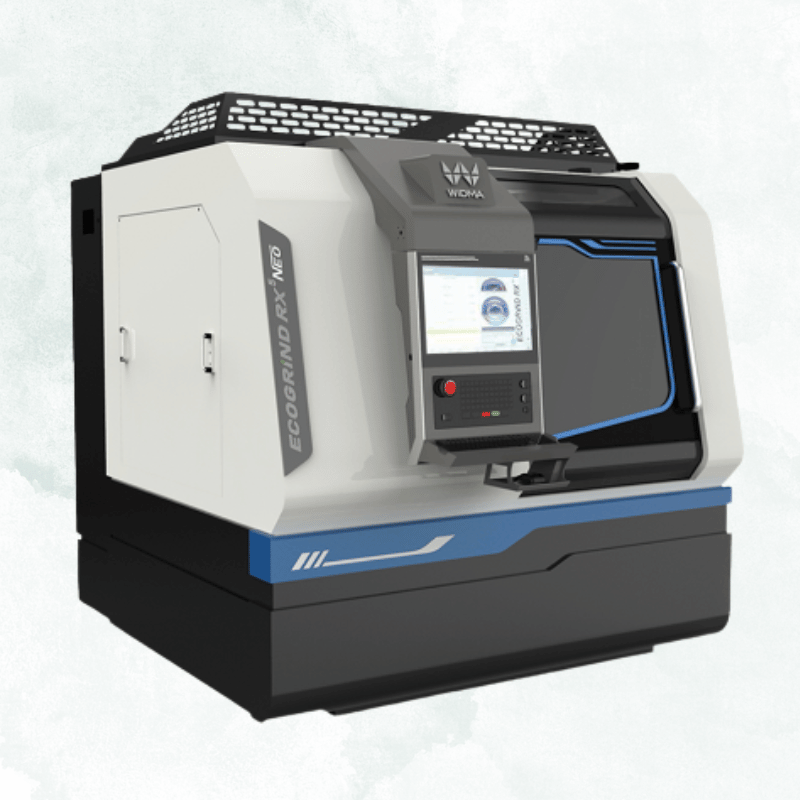

6. WIDMA EZEEGRIND

WIDMA’s tool-grinding portfolio consists of the Ecogrind series, the Ezeegrind series, and the Hobgrind series. The Ecogrind series is designed with premium features to deliver best-in-class productivity and versatility. The Ezeegrind series of machines are suited for mass manufacturing and regrinding of standard tools and select complex tools. The Hobgrind series is ideal for resharpening of hob cutters that are used for gear manufacturing.

Key Features of WIDMA EZEEGRIND

- Wheel probe for measurement of grinding wheel dimensions and flange length distance (FLD)

- Automatic tool probe for measuring and transferring tool offset data to the software

- CNC-traveling steady rest for tools with a higher length-to-diameter ratio

- Automatic fire extinguisher for safety

- Pneumatic counterbalance for vertical axis in addition to electromechanical brake on servo motors

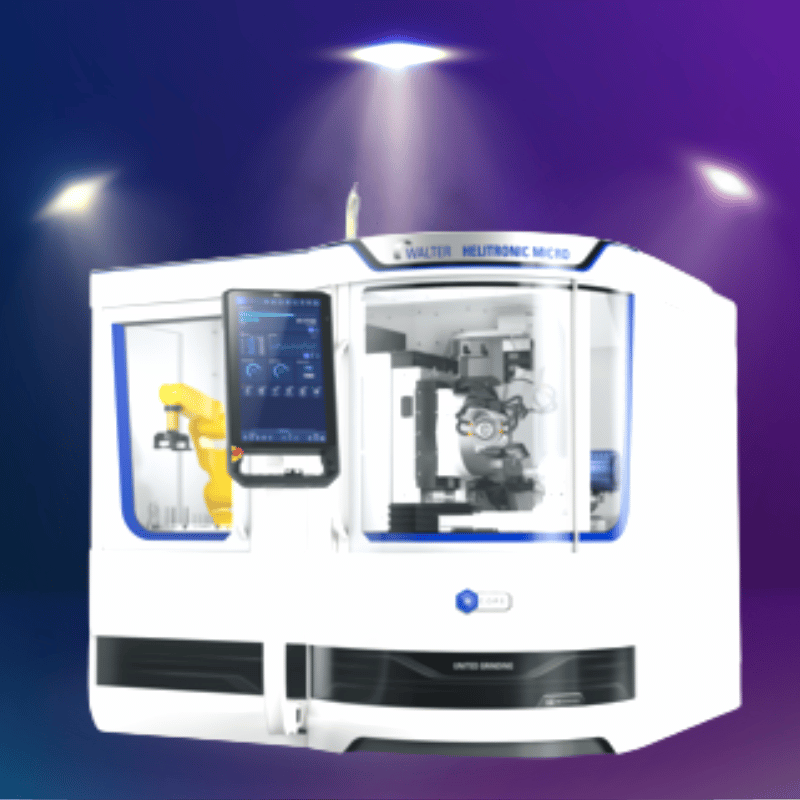

7. WALTER

WALTER CNC machine tools are known for their high performance and reliability and are used in a variety of manufacturing environments, including job shops and production facilities. In addition to its machine tools and cutting tools, WALTER also offers a range of tool holding and work holding systems, as well as software and services for optimizing tool performance and maximizing productivity.

Key Features of WALTER

- High-precision machining

- Advanced control systems

- Wide range of tool holders and workholding devices

- Easy setup and operation

- Wide range of materials

8. TGT

TGT is a brand of CNC (Computer Numerical Control) machine tools manufactured by TGT Precision Technologies, a Taiwanese company that specializes in the design and manufacture of precision machine tools and cutting tools. The company offers a range of CNC machine tools, including lathes, milling machines, and grinding machines, as well as a wide variety of cutting tools, including end mills, drills, taps, reamers, and boring bars.

Applications of TGT

- Precision Machining

- Production Machining

- Prototype and Custom Machining

- Repetitive Machining

- High Performance

9. Zoller Smile 400 Measurement Machine

Zoller is a company that produces a range of precision measurement and inspection equipment. Their products are used in a variety of industries, including aerospace, automotive, medical, and energy, to name a few. Some examples of the types of measurement machines that Zoller offers include:

-

Tool presetters

-

Tool inspection machines

-

Form and surface measurement systems

-

Coordinate measuring machines

It’s worth noting that Zoller is just one of many companies that produce precision measurement and inspection equipment, and there are many other similar products available on the market.

Applications of Lathe

-

Turning cylindrical parts to create precise diameters and shapes.

-

Facing the ends of cylindrical parts to create precise flat surfaces.

-

Creating tapers on cylindrical parts by gradually reducing the diameter of the workpiece.

-

Drilling holes in cylindrical parts using a drill chuck.

-

Knurling the surface of cylindrical parts to create a decorative pattern or to improve grip.

Message Us

Get In touch below. For Heavy Industry Solutions

Call Us

(+91) 9811201119

Office Location

Plot No. 49-B, Bhakari-Pali Road, Pali Industrial Area, Faridabad-121001, Haryana

Open Hours

24*7 Days Working

sales@raxsonstool.com